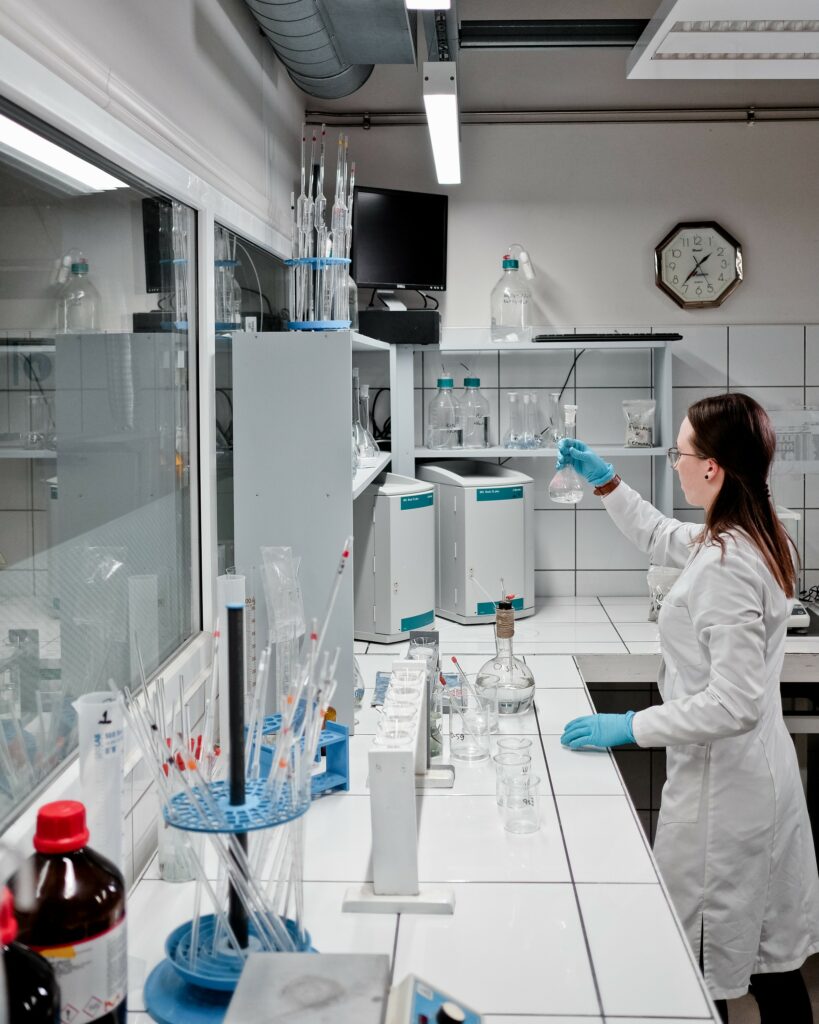

Quality Control

European Union standards and SCHWENK international quality requirements determine quality of cement made in Latvia. We thoroughly monitor manufacturing process and perform laboratory tests of raw materials and ready-made products without compromising any quality traits.

SCHWENK product quality is based on the constant monitoring of the process. We perform control and tests of raw materials with the help of modern equipment – XRF Spectrometer, X-Ray Diffractometer, Laser Granulometer and other devices. Most important physical properties of cement are fineness of cement, soundness, consistency, curing strength after 2, 7 and 28 days, chemical composition.

SCHWENK product quality is based on the constant monitoring of the process. We perform control and tests of raw materials with the help of modern equipment – XRF Spectrometer, X-Ray Diffractometer, Laser Granulometer and other devices. Most important physical properties of cement are fineness of cement, soundness, consistency, curing strength after 2, 7 and 28 days, chemical composition.

European Union standards and international quality standards for SCHWENK establish the quality of cement manufactured in Latvia or other SCHWENK plants in Europe. We closely monitor the manufacturing process and carry out laboratory tests of raw materials and finished products on a daily basis.

Cement quality control complies with European Union standards determining cement control parameters, their frequency and limitations. According to these standards, cement brands CEM II/A-M (S-LL) 52,5 N, Infracement CEM I 42,5 N-SR3 MH/LA manufactured in Brocēni cement plant has received Stability certificate of application properties and CE marking. Company Kiwa performs inspections and issues certifications. Kiwa performs monitoring audit in the cement plant once a year, but control of cement parameters – six times a year.

The cement types CEMI 52.5 R and CEM II/B-S 52.5 N manufactured in Bernburg have stability certificates for application properties and CE marking issued by Vdz.