Sustainable manufacturing

SCHWENK is one of the most innovative building materials producers in Europe and strives to be the leading in sustainable business practice. With responsibility towards environment, global resources and people, we produce highest quality building materials for a broad range of customers. Our environmental standards are one of the highest globally. We constantly monitor the impact of manufacturing on the environment, implementing various environmental protection and preservation activities.

Almost 100% alternative fuel

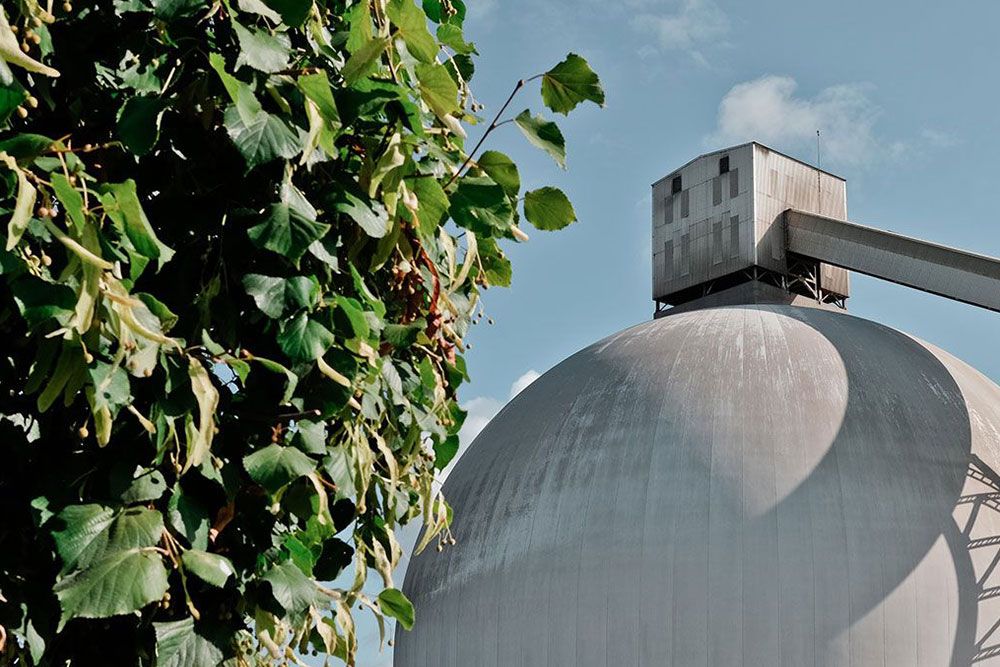

The SCHWENK Latvia cement plant in Brocēni is one of the modern industry examples in Europe where almost 100% of the used fuel is alternative. Its use reduces emissions of the manufacturing process and provides a more environmentally friendly approach. A tempreture of 1500°C-2000°C in the kiln prevents any waste and harmful emissions going into the environment and air.

The plant went into operation in 2010, and specifically built for the use of alternative fuels. All fuels are regularly and strictly controlled before it is used in the SCHWENK Latvija plant. Suppliers perform a full chemical analysis of materials in an independent, accredited laboratory and submit the test results to SCHWENK Latvija before deliveries of these materials. Additionally, tests are also performed in the SCHWENK Latvija laboratory for each freight deliverance to the Brocēni plant. The use of alternative fuel in the plant is supervised and controlled with the operating console and in the laboratory, the fuel is stored in modern storage and ashes produced during the burning process are used in production of clinker.

Alternative fuel used in the plant is specially treated and prepared household and industrial waste (SRF), chipped tyres and neutralized polluted soil. After the use of alternative fuels no wastes of any kind enter the environment. Ashes formed during the fuel burning process bind with introduced raw materials in the kiln, limestone, sand, clay and form the final product – clinker. It is the main constituent of cement. Thus, the type and quality of used fuels also impacts the quality of the final product.

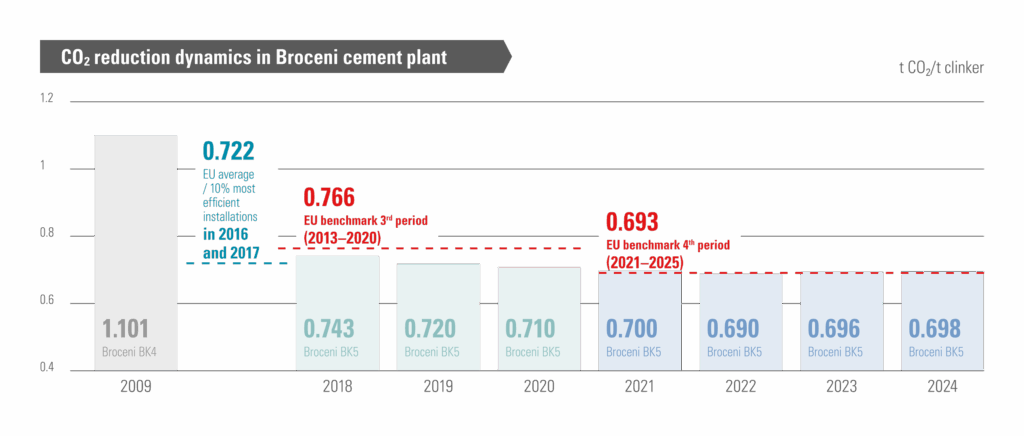

Reduction of CO2 emissions

Level of emissions

Investments in the construction and constant improvement of processes have helped us to noticeably reduce the amounts of emissions in comparison to historical cement plant. This was achieved by the consequent use of alternative fuels for the clinker process and the reduction of the total amount of clinker in the cements we produce. SCHWENK is one of the industry leaders in the reduction of the CO2 footprint and it is one of the most important investment targets in the future.

The newest step in the strategy for reducing the carbon footprint is the evaluation of methods for carbon capture. At the moment two technologies are being tested. One technology is a hot potassium carbonate technology CapsolGo® from Norwegian Capsol Technologies ASA, other one is a physical approach using porous framework for catching CO2 molecules from Canadian Svante. It is envisioned to implement the full scale carbon capture facility by 2030.

SCHWENK Latvija implements a wide program of activities to reduce the consumption of non-renewable natural resources. We perform constant improvements of processes and technologies, heat and modernise buildings, increase efficiency of logistics and use of alternative fuel.

SCHWENK Latvija has an energy efficiency work group constantly monitoring energy consumption and developing scenarios to reduce it. All largest consumers of power – devices and plants are – equipped with separate power consumption meters. This allows monitoring consumption to a high level of detail, to analyse, and better plan modification of equipment and other improvements. We focus on finding ways to improve thermal energy efficiency in clinker production, replacing older devices with modern equipment. For example, the currently used clinker kiln consumes half the amount of thermal energy than the technology used previously. In grinding we use also vertical cement mill that consumes 40% less energy than ball-mill.

Currently we operate together with a local energy provider one of Latvia’s biggest industrial solar energy park. Electricity produced at the solar park is fully used for the cement production in our plant. The 5 500 MWh of annual green energy production deriving from 11 520 solar panels contributes to ca. 5 % of the plant’s electricity consumption. Another solar park is under construction now and is going to be commissioned in 2026.

SCHWENK Latvija achievements in energy efficiency is proved by standard ISO 50001:2012.

Well thought trough logistics planning and training of drivers allows us to reduce impact on environment and costs.

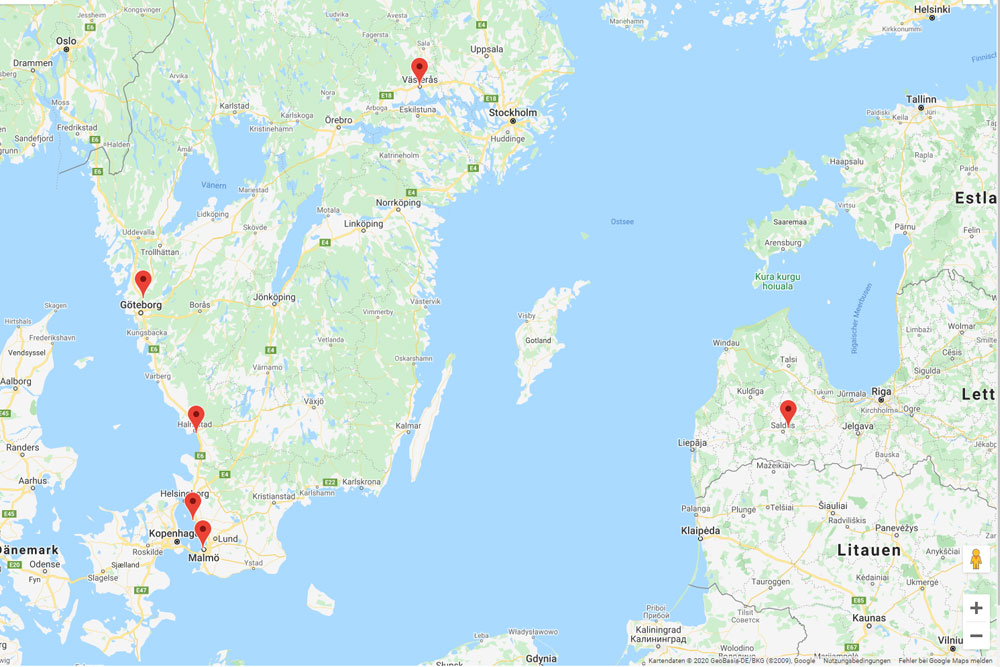

Every day SCHWENK Latvija delivers the manufactured products with around 200 vehicles – bulk cement tanks, bagged cement and aggregates trucks, ready-mix mixers and pumps. We use railway and maritime transport to deliver products to export countries.

It is important for us that SCHWENK shipping contractors are responsible and highly valued traffic participants adhering to safe and defensive driving principles. Sustainable approach in transport organisation is an important part of the logistics team activities. Deliveries are carefully planned, selecting shorter routes with less intensive traffic, and to maximum extent performing deliveries during periods of low-traffic. Our drivers are very responsible towards the cargo and vehicle, they do everything it takes to become a friendly and safe road user.

We also invite other traffic participants to join us in the improvement of the driving style of our vehicles. On the back of SCHWENK Latvija vehicles you will find a phone number for reviews. We are proud that positive reviews and comments are much more than negative. SCHWENK Latvija has repeatedly received the Safest Fleet Awards of the insurance company Balta contest – Safest Company Fleet.

SCHWENK Latvija produces and develops environmentally friendly building materials with responsibly sourced local raw materials – Our production takes place according to highest standards.

We care for the preservation of global resources, which is mirrored in our sustainable business strategy and responsibly manufactured products. We use local raw materials as much as possible, minimizing the logistic network and therefore fuel consumptions and emissions of motor transport. Alternative fuel and alternative raw materials are used in production of cement. These are by-products of other industries and replace natural non-renewable resources and therefore reducing their consumption.

For all our produced cements we have performed a life cycle analysis (LCA), which are documented in form of Environmental Product Declarations (EPD). A LCA analyses the ecological footprint of the cement manufacturing process – beginning with quarrying raw materials to the final product. Greenhouse gas emissions of our cements are given in form of GWP values (Greenhouse Warming Potential). The GWP value represents emissions in form of carbon dioxide equivalents in kg/tonne cement. All EPDs of our cements are published at EPD Norway.

SCHWENK supports principles of the circular economy and takes the responsibility for treatment of manufacturing waste seriously. We do not produce waste water and waste during the manufacturing process in the plant – the manufacturing process is fully cycled in this regard.

SCHWENK Latvija implements a strict internal waste management system. Most of the wastes created in the manufacturing processes are recycled – they return to the manufacturing processes as raw materials and are used in the development of new products.